ECO Keyrings - Production

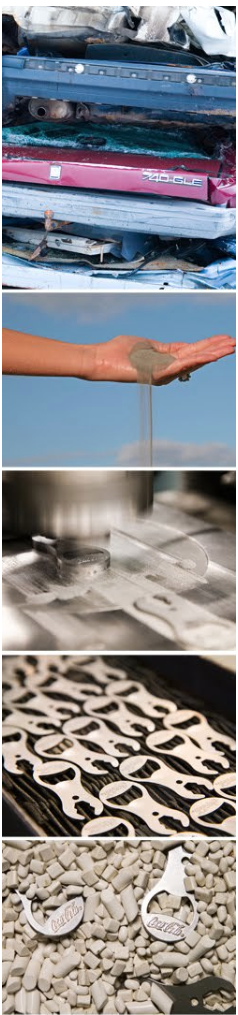

-Metal waste (like old Volvo cars :) is grinded into powder and pressed into a bottlecap opener or trolley coin in Småland, Sweden. Production process contains 18 steps.

-A form is filled with recycled metal powder, to be pressed in a hydraulic press into one piece.

-The logo is made at the same time as the product. Totally integrated in the material.

-After the cold pressing process, the product is fragile as a vitamin pill, and possible to break into pieces.

-To melt the products into one piece of metal, they are heated at 1.120 C in a mesh-belt furnace (sintering) for 30 minutes.

-A hardening process comes next. This makes our products totally unbreakable with a logotype that NEVER fades!

-A polishing process makes them soft and nice for your pocket.

-Finally, assembling of snaphook and ring at the local custody.

All products can be recyclable again as metal. Patented and pattern-protected.

Click HERE for a short introduction.

(Info: Movie, less than 2min. Opens in a new window - Vimeo, HD quality. No advertising like Youtube. We value your time.)

Life Time Warranty

Life Time Warranty on all products! The warranty includes faults from the manufacturing process which makes the product non-usable because of breakage. It also includes a non-fading logotype.

Since all of our products are manufactured in steel – a natural material – they should not be subjected to a lot of water. This is the only thing that you need to keep in mind when making an ECO Keyring your companion throughout life.

Quality and Environment Awareness

In order to guarantee that you get the high quality we promise, we use both digital and videobased machines for measuring. All processes are controlled by FMEA, PPAP and SPS which today are mostly used in the automotive industry.

Of course, we are always eager to improve our operations, we therefore keep a steady communication flow with our customers. New perspectives and suggestions are important and encourages us to develop even better products.

The metal powder we use in our manufacturing process for our keyrings consists of pure iron which comes from nature. The powder is therefore a natural substance which does no harm to our environment. Also, there is no wastage during the manufacturing process - all material is used.

All of our powder presses are manufactured by us in order to keep down our running costs. The are constructed through standard components for quick production cuts would a problem occur. Our World Patent for these smart solutions within this production technique makes these presses half the size of the conventional presses available on the market. Only 20% of the energy used by these ordinary presses are used by our presses. Also, the surplus heat produced in our manufacturing are conserved in a closed system in order to heat our production facilities.

Philosophy

Our business idea is through substantial knowledge, amenability and flexibility offer keyrings of highest quality and just-in-time delivery for you as a customer.

Our operation is recognized by power of initiative, flexibility, a go-ahead spirit and strong environmental awareness.

Our vision is to get even more people to discover the endless usabilities when it comes to ecological keyrings, and to appreciate the everlasting messages they all send 24/7 - until the end of all times.